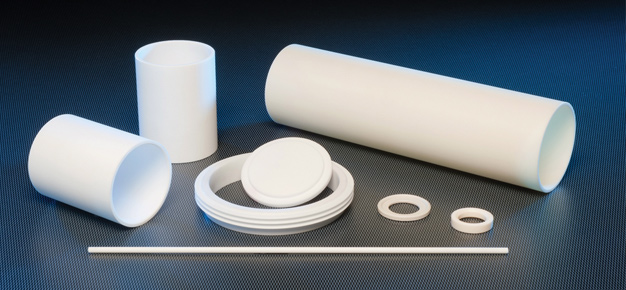

Alumina Ceramic - Aluminum Oxide

What We Do

Physical Properties Of Associated Ceramics Alumina

Modern alumina (Al2O3) products are among the strongest and hardest of all ceramic materials. They also have a high dielectric strength, and at elevated temperatures such as those encountered in many applications, their electrical resistance is excellent. Alumina ceramics also feature very high mechanical strength, high thermal conductivity, and high resistance to chemical and corrosion attack at room and elevated temperatures. Further, this valuable class of materials can be made extremely hard - second only to diamond on the Mohs’ scales for resistance to wear and abrasion.

Many of alumina’s outstanding properties can be enhanced through variations in manufacturing methods and in chemistry. Associated Ceramics has earned a reputation for achieving dimensionally accurate alumina parts with excellent quality and reproducibility. The following table describes many common alumina bodies; we can work with other formulations as well.

Table converts to a left/right scrolling table when viewed on mobile devices or smaller screens.| ACT Material Code > | AC-AL1090 | AC-AL850 | AC-AL900 | AC-AL920 | AC-AL940 | AC-AL960 | AC-AL980 | AC-AL8020 | AC-AL998 | AC-ZTA | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Description > | 80% | 85% | 90% | 92% | 95% | 96% | 98% | 99.5% | 99.80% | Zirconia Toughened Alumina | |

| Color | - | White | White | White | White | White | White | White | Ivory | Ivory | White |

| Density | g/cc | 3.40-3.45 | 3.45-3.50 | 3.55-3.60 | 3.60-3.65 | 3.70-3.75 | 3.70-3.75 | 3.75-3.80 | 3.75-3.85 | 3.90-3.95 | 4.00-4.05 |

| Porosity | % | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 | 0-1 |

| Flexural Strength |

psi (MPa) | 40,000 (276) | 42,000 (290) | 45,000 (310) | 47,000 (324) | 48,000 (331) | 50,000 (345) | 52,000 (358) | 50,000 (345) | 54,000 (372) | 60,000 (414) |

| Compressive Strength |

psi (Mpa) | 260,000 (1,792) | 280,000 (1,930) | 300,000 (2,068) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) | 350,000 (2,413) |

| Tensile Strength |

psi (MPa) | 21,000 (145) | 22,000 (152) | 30,000 (205) | 32,000 (221) | 30,000 (205) | 32,000 (221) | 35,000 (241) | 32,000 (221) | 40,000 (276) | 42,000 (290) |

| Elastic Modulus |

psi x 106 (GPa) | 32 (221) | 32 (221) | 40 (275) | 42 (290) | 44 (303) | 44 (305) | 50 (345) | 50 (345) | 54 (372) | 50 (345) |

| Fracture Toughness |

MPa/m | 3-4 | 3-4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 |

| Dielectric Strength |

Volts/mil | 250 | 250 | 210 | 210 | 210 | 210 | 220 | 210 | 220 | 210 |

| Dielectric Loss Tangent |

@ 1 MHz | 0.0004 | 0.0004 | 0.0004 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0001 | 0.0005 |

| Thermal Conductivity |

W/m°K | 16.0 | 16.0 | 17.0 | 20.0 | 22.0 | 22.5 | 27.0 | 27.0 | 30.0 | 27.0 |

| Coefficient Of Thermal Expansion |

1 x 10-6/°C | 7 | 7 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Safe Use Temperature |

°F °C |

2400 1315 |

2600 1425 |

2700 1480 |

2850 1565 |

3000 1650 |

3000 1650 |

3100 1700 |

3200 1750 |

3100 1700 |

2700 1480 |