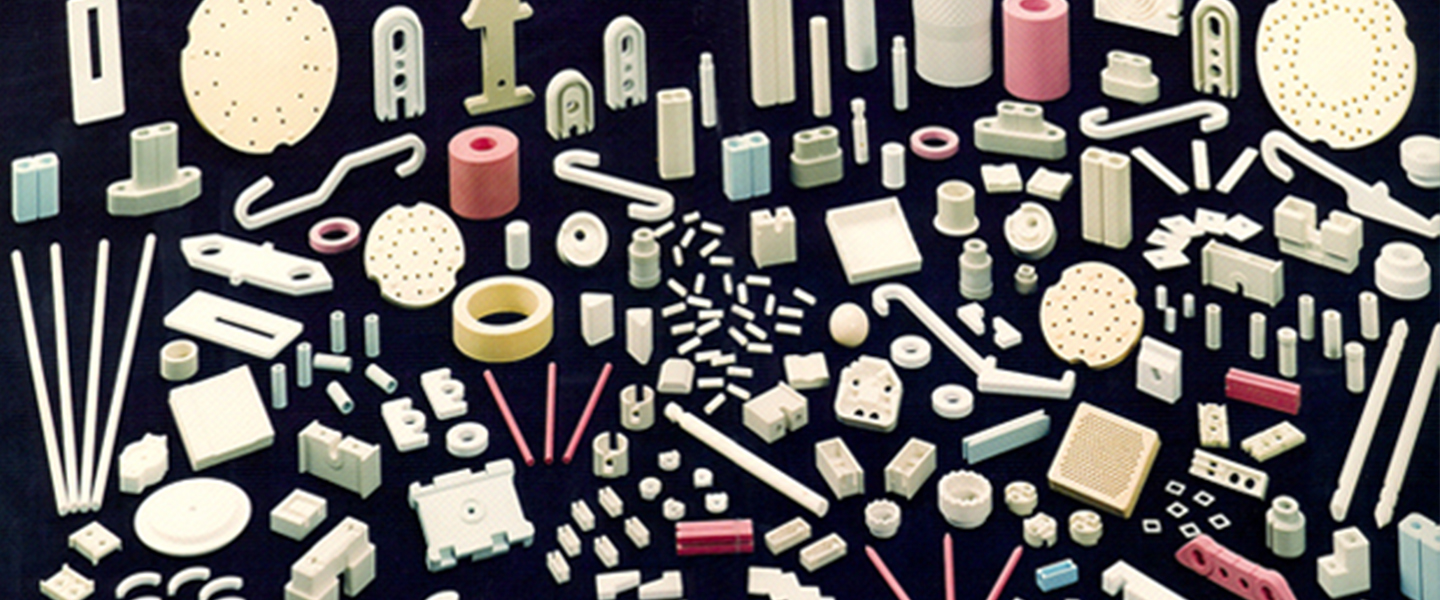

We are a global manufacturer and supplier of technical ceramic materials and components. Our custom manufactured products are used across various industries for heat/electrical insulation, wear-resistance, chemical and industrial applications.

What We Do

About Us

At Associated Ceramics & Technology, Inc., we distinguish ourselves from our competitors with our ability to assist our customers in the engineering specifications of their complex ceramic parts. We have a full service design and manufacturing team. We have ceramic engineers, manufacturing engineers, and tool designers involved in every project from inception. By involving this specialized team from the beginning, we are able to assist our customers in designing a product that meets their requirements for physical and chemical properties. These products can be fabricated at high volumes and at the lowest possible cost. Throughout the design process our team focuses on the quality of the design and the ability to produce quality products.

The ceramic engineers are able to address the required physical and chemical properties of the finished product. These same engineers oversee the daily preparation of the ceramic bodies used in manufacturing. They know the product and the processes and what is required for every application.

The tool designers are able to provide input in the design of a tool which will be cost effective to make and maintain. These same designers manage the manufacturing of the tools which will be used to produce the finished product. We have an in-house tool shop to create our tools on sight for the best quality and least cost to our customers.

ACT has two manufacturing facilities to produce over 1.2 million parts per day. We have a worldwide customer base that relies on our continued commitment to quality and your success.